Shop update 2022 I have updated this page several times so it's not

really organized. It's just when I got around to adding some stuff to

it. It's a mishmash of stuff! Several pages with pictures below!

I have been blessed over the years with many hours of

extra work. When the weather over the past 40 years is bad and most folk

are looking out the window they may just see me out side fixing lines for at&t.

This job has blessed me with thousands of hours of over time pay. So

picking up tools every month or so has been made possible. Now mind you

those 40 years of some years of 500 plus hours of overtime...were often forced.

YUP no choice had to be out in that stuff heat advisory hot or bone chilling wet

cold lots of ice and snow storms. Yet my solstice in that was I had mad

money for Rangers and Woodworking. I am blessed. In my work

going into any place one can imagine the rich, the poor the clean and the

filthy. The healthy and the sick. The hard worker and the lazy.

I have seen more than most folk will ever witness. I have been in places

that few get to see. The highest to the lowest. Been in tens of

thousands of homes and a thousand business. Seeing folk where they live

and work. A perspective view I have.

So I love Royal Ranger Ministry and woodworking and backpacking. The re-sawing

bandsaw will allow us to take a group of boys to the woods and cut down

trees with chainsaws into logs we can move about four feet long or less and then

resaw that into useable lumber for Ranger projects and even some Frontiersman Camping Fellowship furniture

and neat stuff. I was blessed by Central AOG for some 15 years to have a

shop there at their Ranger Annex and do these very things I have talked about.

Last year or so moving my tools home gave me the opportunity to make things

mobile and to have time to refine ways and means. Always learning and

trying to do right. I want to thank Rob Batchman not pictured here and my

son Marshall for

coming over and helping setup and man handle this beast of a band saw.

God has blessed me with great friends. Work hard. Play hard.

Love God. HE WILL BLESS YOU! Heaven is better than this place.

Until then. REACH, TEACH, KEEP Folk for Christ.

Click on a

picture for a larger view.

Wooden Canteen Project

Dec. 2021

Red Cedar Lantern

Project 2021 Box

Making Gadget in Vcarve 2021

CNC Router Relay and Box

2021 CNC

Controler Card Replacement

How I sharpen Bandsaw

Blades (best I have found)

Resawing Walnut log 2021

Shop updates and CNC

Machine updates and tweaks 2021

13 Cedar Plaques CNCed

Video 3d

printer page March 31, 2021

Paint

Booth 4 position made out of blue foam.

February 1st Box Fan Air

Scrubber on the Cheap!

January Canteen project part 1 overview

January

Canteen project part 2 more indepth

January

Canteen project part 3 attaching straps and waterproofing

February

Canteen project part 4

January Shop Vac

Sound Box. and

Report on

this box.

December Lantern Project

ended up making 16 lanterns for a fundraiser for Rangers.

December Thermos Project

Made two of these Thermos Wooden covers. Lid twists off. Fun

project.

11-10-2020 Make

Wooden Dowels with this cool jig. I made about 60 dollars of hardwood

dowels 3/8" and 1/4" out of scrap that was heading for the fire pit.

09-26-2020 CNC Shop

Addition with some video and projects.

06-01-2020 Box Joint Jig Very configurable. From 1/4" box joints to any size

in 1/4" increase in size and a mix and match if one wants to do that. Very

repeatable and can cut 24 sides at a time if needed of 1/4

" stock.

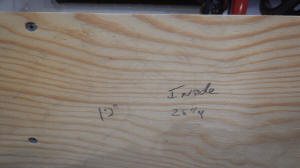

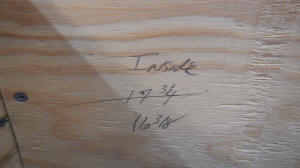

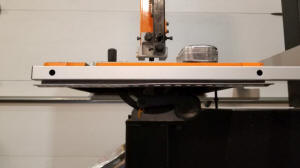

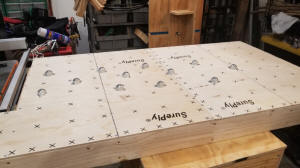

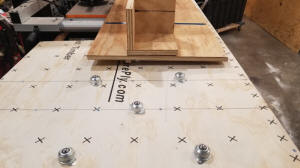

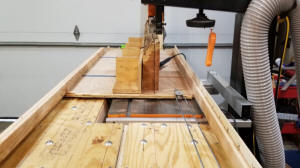

06-20-2019 I made a new sled. It is side guided and covers the whole 28" of table width.

The guides along each side and the resaw sled is made out of Red Oak 3/4"

plywood. The undercarriage is supported by 3/4" eye socket bearings placed

on about 12" apart. The new resaw sled works great. The Winch pulls

it slowly through the blade and the counter weight pulls the sled back when the

winch is in reverse. The sides guide this new sled and the sides have

hold down limits so the weight doesn't lift the sled off the table. Click on a picture for a larger view.

08-01-2020 Resaw Sled Full width pictures. Resawing

a Old Walnut Log on the Resaw Sled

You Tube Video on the

New 28" Sled setup and table and winch.

Time Lapse of Resaw Table

Assembly and what I leaned about 11.25" Red Oak Resaw and the Grizzly 17" 2hp

Bandsaw.

Resaw Table video

3 minutes.

Resawing 8 Cedar Logs.

Setting up the

Resaw Sled and cutting 5 boards using the winch in fast motion.

Maple

Resaw 05-22-2020

Hercules 12" crosscut

saw on a a Harbor Freight Stand (they have a new Hercules stand out a bit

heavier) How I use it and store it. The older stand is not heavy duty

enough. It is now breaking at the welds.

Resawing 4 big

walnut logs 4' long by 12" round. It's 42 minutes long. So you

may need to use the slider to get past some of the parts. I removed about a

hours worth of cleanup and fiddling!

Resawing on my

12" Delta Bandsaw modified with a resaw table and a larger grizzly motor.

This is hard to do and very time consuming. Hence the work started to

build a resaw sled.

Walnut was resawed and then stickered then ends sealed in parifin wax then

restickered then moved down into the shed. Resaw Table was cut in half and glued

and then stored up in the attic for future use.

Well I had a glitch in my web publishing software and lost the grouping and

text for these pictures.

These sleds gave me ideas to use. Thanks to these folk that paved a way

for ideas to flow.

Link to the video

on this setup.

God's way is always the BEST way!