June 3rd 2020 Box Joint Jig. After reviewing 3 weeks of youtube

videos on box joints I decided on this setup. I don't know who the

original idea guy was but the Wood Father had some great ideas and #24 Box Joint

was very good as well. I am so thankful for youtube authors that share the

great ideas they have. This jig is simple and configurable on the fly.

I plan on cutting 10 3/8 thick box sides at a time in a batch mode.

I will use two 90 degree fences on the 2 t slots and sandwich the stock in

between them. One fence will have some T slot clamps on the face

of it to hold the stock in tight. As of now with the one fence I can cut 4

sides at a time. The T slot fence will at sometime have a replaceable waste

bottom put on it or I will trim it up from time to time. I can use a waste

board behind the stock to stop tear out. The t-slot fence is

screwed onto the other fence so when I tighten down the t slot clamps it won't

pull the T slots out of the grove. It's a bit over 1" of plywood instead of

3/8" of plywood.

I was able to sand and clean up this jig and add another fence. The

above link is talking about this update. The following set of pictures is

from the previous 3 days of the build process. This jig works great!

|

|

|

|

Box Joint Jig

|

|

|

|

Plywood Fingers 1/4" by 1.5" x 2.25" ReadyBackerHardwood

|

|

|

|

|

|

|

I moved this knob 3 times as my jig fingers were flexing.

|

|

|

|

Sizing up the fence for T -Slot tracks

|

|

|

|

I was thinking weight would be a issue but its not in use.

|

|

|

|

|

|

Shown Tslot clamps

|

|

|

|

Old Crayon Box I am wanting to make a bunch of these.

|

|

|

|

One other guy on youtube had this box as well.

|

|

|

|

|

|

|

My first box joint cuts

|

|

|

|

I cut them a bit proud but can sand them off.

|

|

|

|

|

|

After taking the flex out of the jig fingers it worked perfect.

|

|

|

|

No glue on these yet.

|

|

|

|

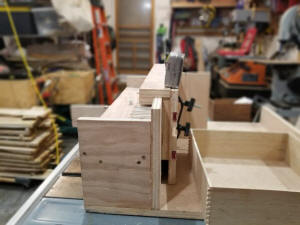

Side view of Jig

|

|

|

|

|

|

I have one finger out for a quick tool to line stuff up.

|

|

|

|

Piano Lid will get one more board added to lock the fingers down as well as in.

|

|

|

|

T-nut. I moved this 3 times. HA!

|

|

|

|

|

|

I will clean this up with some vineer and putty.

|

|

|

|

Fence with tslots installed will have 2 90 degree fences for batch work.

|

|

|

|

Shows the stop board out on the lower left.

|

|

|

|

|

|

|

I will make one more of these 90 degree fences for other side of boards I am cutting.

|

|

|

|

T slots didn't have holes in them. I had to drill them and counter sink the holes before I installed them.

|

|

|

|

|

|

These tslot clamps held very well for 2 pieces at a time.

|

|

|

|

My first box cut with this jig.

|

|

|

|

With glue these are tight enough. I can change out the drill bit with something a couple thousands bigger and It would be perfect and tight.

|

|

|

|

|

|

Was very pleased this thing worked perfect once I got the flex out of the jig fingers.

|

|

|

|

Will remove these hold down fingers for batch work and use another 90 degree fence

|

|

|

|

Jig shown with the fence down about 4" after cutting the box joints.

|

|

|

|

|

|

|

Piano hinge locks in the fingers.

|

|

|

|

|

|

|

The drill bit pin that is just 0004 mill less than the saw blade is inbetween the first jig finger the side.

|

|

|

|

Jig finger I placed on the top edge to show it's moved in one finger on the second set. This finger is just for show it's not doing anything.

|

|

|

|

When I set this up for the first set of boards The fence is all flush with the side of the jig. In this case it's moved over one finger.

|

|

|

|

|

|

Another shot of the fence being over 1 finger

|

|

|

|

I can cut 1/4" or any combination of 1/4" box joints. 2" box joints no problem just rearrange the fingers.

|

|

|

|

|

|

|

Slide stopper. It's simple and quick and it swings up.

|

|

|

|

|

Stopper bloxk swung up out of the way.

|

|

|

|

|

|

|

Stopper block swinging out of the way.

|

|

|

|

Nice jig. I can't wait to cut some oak and make the box joints. I have some 3/8 red oak all ready!

|

|

|