July 26th, 2015. 8 hours of work got us to this point. Most of this

boat was assembled by me a couple of hours at a time. The main sheets and

ribs were made and cut out by the boys on Sunday night. 5 days later the

boat took this form. The sheet of card board is 15 ' 2" by 6'

5" it's one and a half times the thickness of regular cardboard.

No wood or screws remain in this boat. It's all cardboard, glue and paint.

Click on a picture for a larger view.

|

|

|

|

You need pressure and weight for a strong joint

|

|

|

|

Discarded marble counter tops are great weights

|

|

|

|

Ribs and 3" wide flaps make good joints

|

|

|

|

|

|

Temporay supports to hold the boat in shape while glueing

|

|

|

|

|

I used old fence boards and the deck screwes for clamping

|

|

|

|

|

|

|

these deck screws are the best 2 threads pull joint tight get square headed instead of phillips to keep them from stripping out

|

|

|

|

Keep weight on all the glueing surfaces for 20 minutes.

|

|

|

|

|

|

Anything works for weight. Flat surfaces are best

|

|

|

|

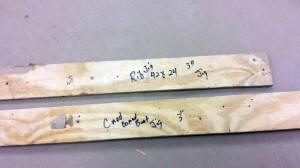

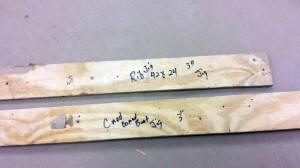

These are 3" jig boards that match the ribs in lenght and width plus they are 3" wide to mark the flaps.

|

|

|

|

All the tools you need to make a good boat not showing the weights

|

|

|

|

|

|

|

|

It's neater if you can squeeze glue out of a bottle. On big flat surfaces I just pour it from the bottle. besure to thin the glue

|

|

|

|

|

|

This little red tool is handy for making cuts.

|

|

|

|

|

The square head screws and cordless drill and the 2 chipboards on each side of the cardboard make the best clamping system I have found.

|

|

|

|

|

|

|

|

This stack was 4 feet tall... Many years of fun!

|

|

|

|

|

|

Added another rib in the front and back section

|

|

|

|

|

Harbor Freight will have these on sale for about a buck a piece. Buy 25 at a time. Very handy

|

|

|

|

|

|

Glueing on the top deck will cut holes out in a few.

|

|

|

|

Besure to remember where the ribs are I measured from the back of the boat.

|

|

|

|

Weight slides down hill so added some screws to hold the weights from sliding down. This is a closed in part and no chipboard could be used on this.

|

|

|

|

|

|

|

|

|

|

|

Placing it on the side and first glueing the side that is on the bottom added weights then did the same on the upper side.

|

|

|

|

Need lots of weights. Landscaping step stones will work as well.

|

|

|

|

|

|

|

|

Flaps must over lap the joints

|

|

|

|

|

|

|

I put down 4 sheets of card board as a work surface and use them for the boat launch at the lake and to cover the card board for the return burn pile.

|

|

|

|

|

|

|

|

Don't leave the weight on over night. It could mash your boat or cause it to sag.

|

|

|

|